JCJZ 六色机组式高速高清柔版印刷机 科赛套色系统 日本三菱控制 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 详细信息 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

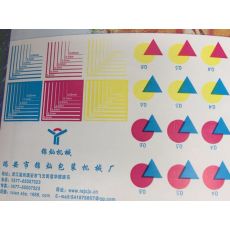

设计来源:根据意大利客户提供的视频图片及要求,吸收柔版印刷机的元素,共同开发的一款组合式柔版印刷机。 Design source: based on the video images and requirements provided by Italian customers, it absorbs the elements of flexographic printing presses, and jointly develops a satellite composite flexographic printing press 特点Features: 1.从放料到收料超短距离。 From the discharge to receiving a very short distance 2.自主研发的特制刮刀,弥补高速飞墨,减少了溶剂在空气中的挥发。 Self-developed special scraper to make up for high-speed flying ink, reducing the solvent in the air of volatile. 3.反复印刷长度260-635MM,填补层叠式柔版印刷机印刷长度不够的空白。 Repeated printing length 203-635MM, to fill the laminated flexo printing machine printing length is not enough blank. 4.采用卫星式轮转机套色方式,套色精准,印刷稳定。 Using satellite rotary machine sets color, color chromatography precision, printing stability.

5.承印材料:PVC:35~70μm OPP:20~70μm BOPP:20~60μm PE:35~100μm NY:20~50μm PET:20~60μm CPP:20~60μm纸张:20~250g/㎡不干胶等材料。 Printing material: PVC: 35 to 70 μm OPP: 20 to 70 μm BOPP: 20 to 60 μm PE: 35 to 100 μm NY: 20 to 50 μm PET: 20 to 60 μm CPP: 20 to 60 μm Paper: 20 to 250 g / Other materials.

5. 制版周期短、成本低制一副多色凹版滚筒的周期为5〜10天,而柔印版制作为5小时。柔性版视印刷面积而定版材大小,比凹印滚筒成本低得多。 The period of plate making is short, the cost is low, the period of multi-color gravure cylinder is 5-10 days, but the flexography is 5 hours. The flexography depends on the printing area and the size of the plate, which is much lower than the cost of gravure drum. 6. 印前预热,印后风刀干燥设计。解决卫星式印刷机各印刷单元之间距离太短,油墨干燥不良时容易造成的蹭脏。 Pre-pre-press, printed after the wind knife drying design. Solve the satellite printing press between the printing unit is too short, easy to cause dirty ink dirty.

8.1-6色可根据需要定制,宽度300-1600根据需要定制。 1-6 color can be customized according to need, width 300-1600 customized according to need 9.工艺1放料、2自动恒张力、3刮刀、4印刷单元、5牵引、6自动恒张力、7收料 Sections:1 discharge, 2 automatic constant tension, 3 scraper, 4 printing unit, 5 traction, 6 automatic constant tension, 7 receipts

主要技术参数Main Technical Variables:

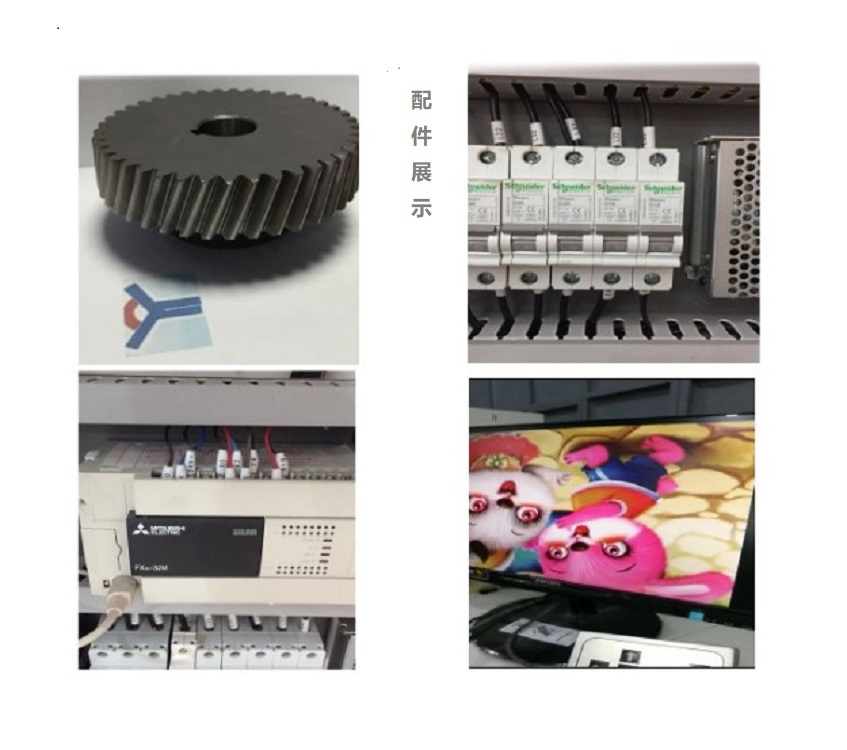

电器清单

|

| 我的瑞网企业目录 |